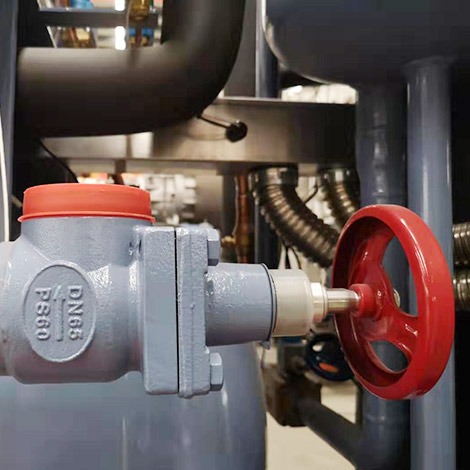

CO2 Check Valve, Stop Check Valve Angle Type

The stop check valve is mainly used in the pipeline which only allows the medium to flow in one direction and prevents the reverse flow. Under the action of the fluid pressure flowing in one direction, the valve disc opens; when the fluid flows in the opposite direction, the valve disc acts on the valve seat by the fluid pressure and the self weight of the valve disc, thus cutting off the flow. It can be used to prevent the backflow of medium on various pipelines of refrigeration system. . stop check valve can also be used as stop valve. The products are mainly divided into straight stop check valve and angle stop check valve.

Product Information

Angle Type

CO2 Check Valve

What is a co2 check valve?

The check valve used in the co2 pipeline is the co2 check valve. We often use co2 check valve in the piping system. This is because different pipelines will carry different valves.

How do you install a co2 check valve?

So in short, take the check valve, blow into it. If air can pass through, take that side attach it to the tubing coming FROM your air source. Attach tubing to the other side of the check valve and attach your air stone or CO2 diffuser on the end of that side. Until next time, keep your thumbs aquatic!

Stop Check Valve PS60 Series:

Technical Parameter

Nominal Diameter: DN15-DN200

Nominal Pressure: 4.0 MPa

Applicable Medium: R12, R22, R502, R134a, R404a, R507, R717 and other refrigerants.

Applicable Temperature: -46 ℃ ~ + 150 ℃

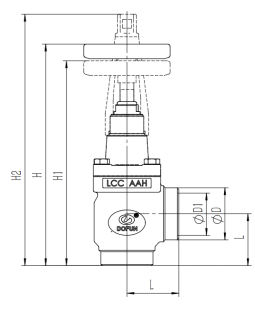

Structure Form: Angle Type Structure code is A ,Straight Type Structure code is B

| Angel Type PS 60 Stop Check Valve | |||||||||

| Type | Nominal Diameter(DN) | Size(mm) | |||||||

| L1 | L2 | H1 | H2 min | H3 max | H4 | H5 min | H6 max | ||

| SCV-A | 15 | 45 | 45 | 230 | 189 | 210 | 230 | 189 | 210 |

| 20 | 45 | 45 | 230 | 189 | 210 | 230 | 189 | 210 | |

| 25 | 45 | 49.5 | 230 | 189 | 210 | 234 | 193 | 214 | |

| 32 | 49.5 | 62 | 242 | 204 | 228 | 318 | 242 | 273 | |

| 40 | 56 | 62 | 312 | 236 | 267 | 318 | 242 | 273 | |

| 50 | 60 | 65 | 297.5 | 232 | 254 | 302.5 | 237 | 259 | |

| 65 | 70 | / | 325 | 258.5 | 288 | / | / | / | |

| 80 | 91 | / | 381 | 306.6 | 332 | / | / | / | |

| 100 | 107 | / | 416.5 | 336.8 | 372 | / | / | / | |

| 125 | 133 | / | 557 | 444 | 500 | / | / | / | |

| 150 | 146 | / | 592 | 480 | 530 | / | / | / | |

| 200 | 180 | / | 716 | 548 | 618 | / | / | / | |

Stop Check Valve PN63 Series:

Technical Parameter

Nominal Diameter: DN15-DN150

Nominal Pressure: 6.3 MPa

Applicable Medium: CO2,R12, R22, R502, R134a, R404a, R507, R717 and other refrigerants.

Applicable Temperature: -46 ℃ ~ + 150 ℃

Structure Form: Angle Type Structure code is A ,Straight Type Structure code is B

| Angel Type PN 63 Stop Check Valve | |||||||||

| Type | Nominal Diameter(DN) | Size(mm) | |||||||

| L1 | L2 | H1 | H2 min | H3 max | H4 | H5 min | H6 max | ||

| SCV-HA | 15 | 45 | 45 | 230 | 189 | 210 | 230 | 189 | 210 |

| 20 | 45 | 45 | 230 | 189 | 210 | 230 | 189 | 210 | |

| 25 | 45 | 49.5 | 230 | 189 | 210 | 234 | 193 | 214 | |

| 32 | 49.5 | 62 | 242 | 204 | 228 | 318 | 242 | 273 | |

| 40 | 56 | 62 | 312 | 236 | 267 | 318 | 242 | 273 | |

| 50 | 60 | 65 | 297.5 | 232 | 254 | 302.5 | 237 | 259 | |

| 65 | 70 | / | 325 | 258.5 | 288 | / | / | / | |

| 80 | 91 | / | 381 | 306.6 | 332 | / | / | / | |

| 100 | 107 | / | 416.5 | 336.8 | 372 | / | / | / | |

| 125 | 133 | / | 557 | 444 | 500 | / | / | / | |

| 150 | 146 | / | 592 | 480 | 530 | / | / | / | |

| 200 | 180 | / | 716 | 548 | 618 | / | / | / | |